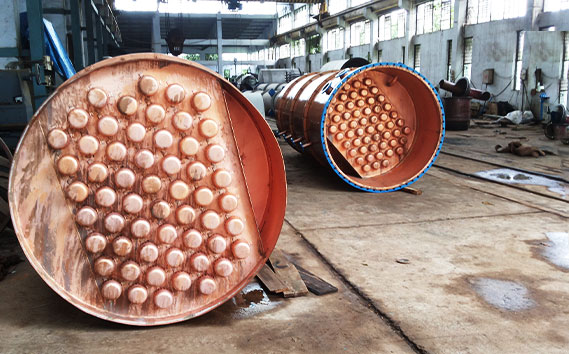

We at Attomo provide the manufacturing, turnkey supplier, designing and engineering consultation of the bubble cap tray. The Bubble Cap Tray is a type of tray that has been used for a long time. These trays are known as “fluid fixed” trays, where vapour passes through short lines known as risers covered by a cap with a serrated edge or spaces. These valves are typically used in situations where leakage is not permitted and for handling low liquid loads. Additionally, they have a high turndown ratio. The design is efficient and suitable for specified applications like the Chemical industry, Pharmaceutical Industry, and Petrochemical Industry.

At the heart of Attomo Industries’ Distillation Bubble Caps lies their ingenious design, which allows for efficient separation and purification of various substances. The precision engineering of these bubble caps ensures an even distribution of vapour and liquid flows, promoting effective contact between the two phases for enhanced mass transfer. This results in improved separation efficiencies and enhanced overall distillation performance.

The raw materials used for manufacturing Distillation Bubble Caps are primarily Copper, Titanium, and Stainless Steel. These materials are chosen for their excellent properties and suitability for the demanding requirements of distillation processes.

| Bubble Cap Trays are available in the following types | |

| MOC | Copper, Titanium, Stainless Steel or any metal/combination as per client requirement. |

Applications:

- Amine Absorbers

- Amine Regenerators

- Caustic Towers